What is FUTURELIGHT? – The North Face Launches New Fabric in Aspen, Colorado

Forget about what you thought about technical outerwear. The North Face’s FUTURELIGHT aims to change the game, and is poised to shake up the industry standard.

To introduce their new material, The North Face (TNF) orchestrated a media launch in Aspen, Colorado last week. They invited endemic and mainstream media to experience FUTURELIGHT in an authentic way, alongside their top-tier snow athletes and alpinists.

Premium testing grounds.

Premium testing grounds. Why Aspen?

It’s four separate ski areas, steep peaks, and bountiful backcountry provided the perfect terrain for the diverse group, and allowed everyone to experience the material in a honest, tangible way, regardless of snow skill.

It’s also the home of both Scott Mellin, Global General Manager of Mountain Sports at The North Face, and Nate Rowland, a TNF alpinist who’s been instrumental in the testing phases of FUTURELIGHT.

Rowland, a bonafide mountain goat that has summited peaks within the Tien Shan of Kyrgyzstan, the Andes of Patagonia, the Aleutian Islands, the Tordrillos, the Chugach and beyond, and was said to have worn the same FUTURELIGHT kit over 100 straight days while testing. Throughout it all, his kit’s specs never wavered from day one to day 100.

Clad in the original TNF signature yellow, our group was prepared to test the future.

Clad in the original TNF signature yellow, our group was prepared to test the future.So just what is FUTURELIGHT?

We had heard rumors of this new technology around Winter Outdoor Retailer, but didn’t come face to face with the material until we checked into our room at the Limelight Hotel Aspen on night one of the three day launch.

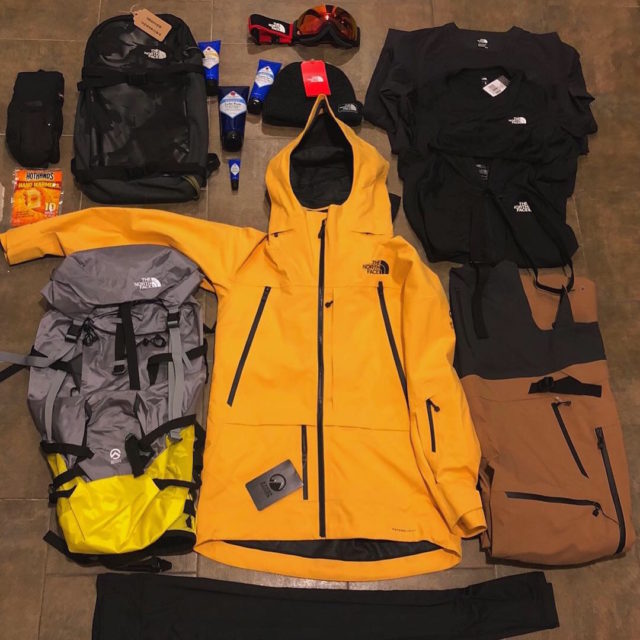

Greeted with a crisp new kit that included the Women’s A-CAD Jacket and Women’s A-CAD Pant (both part of TNF’s Summit Series, a category best-suited for freeriding), we were instantly taken with the feel of the material. It was supple and alluring to the touch. This initially made us wonder how would it perform in the backcountry.

And, what the heck was it made of?

A bounty of TNF goods, along with the Women’s A-CAD Jacket and Women’s A-CAD Pant.

A bounty of TNF goods, along with the Women’s A-CAD Jacket and Women’s A-CAD Pant.That first night, we settled into a presentation by Scott Mellin, who walked us through the inception of FUTURELIGHT.

“When we think about innovation at The North Face, it has to come from a pure point of inspiration,” Mellin began as he introduced the origin of his brand’s latest concept.

He elaborated with a story about how he and TNF alpinist Andres Marin were on a ‘classic alpine day’ on Mount Sneffels outside of Ouray, Colorado. Throughout the mission, the duo experienced the classic take-the-shell-off, put-the-shell-back-on jig, as the weather warmed or when wind picked up.

Post-trek when they reached the car, Andres mused, ‘Man, wouldn’t it be so great if we could just keep our shells on all day, and then you wouldn’t have all this, on-off, stuff which actually greatly increased our exposure to risk?”

Mellin took that notion to his lead TNF designers in their headquarters in Alameda, California (soon-to-be-Denver). “We should be able to tune these fabrics in a way that allow us to create different levels of air-permeability and waterproofing, so we can optimize them for skiing, riding, ski mountaineering and beyond, no matter how the weather changes throughout the day,” Mellin told his team.

Understanding the need for a reimagined fabric, the designers acknowledged it would require a big change, and one that needed to be inline with the TNF’s sustainability efforts.

[In order to accomplish this], ‘we had to make a big pivot’, said Mellin. “From being a brand that buys ingredients to make them into different combinations, to being a brand that creates its own science.’

With this new goal set forth, TNF began the meticulous process of creating its own proprietary fabric, rooted in functionality and sustainability.

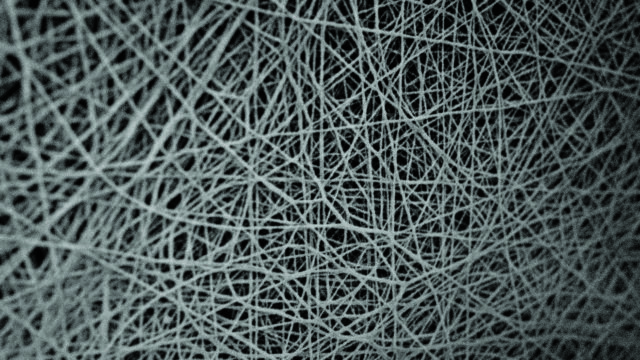

Nano-spinning. Image: TNF

Nano-spinning. Image: TNF“The real magic of FUTURELIGHT is where we moved from extruded plastic into nano-spun polymers,” Mellin explained. “By spinning fibers at 200 nano-meters of dimension to create an incredibly porous film that exhibits total waterproofing, we’re increasing our moisture-vapor transmission rate to air-permeability, therefore yielding a completely waterproof product. It’s incredibly light and thin…. State of the art in every sense of the word.”

Breathable and waterproof? Photo: TNF

Breathable and waterproof? Photo: TNFTNF’s fabric innovation has allowed them to create their most sustainable three-layer jacket they’ve ever produced, through the use of recycled materials, the use of non-PFC DWR finishing, and is produced in factories with sustainable practices.

While this material excelled in the lab, it also needed to be accepted and backed by TNF’s world-class athletes. So they put FUTURELIGHT on the backs of those summiting the world’s highest peaks, including Everest, Lhoste, and Cho Oyu.

“It’s one thing to create fabric that measures really well in a laboratory, but for our brand, it’s super important it’s athlete-tested and expedition proven,” Mellin quipped.

With the hardcore testing already done by elites in the most extreme environments, how would it do for us, snowboarders?

Now for the real test.

Official testing photo.

Official testing photo. For the next part of the launch, we were split in small groups with an athlete and a guide from Aspen Expeditions. We went on our own mini-expeditions, traipsing our way up and down faces of the Elk Mountains. Our group was led by Jack Cody, a renowned snowboard mountaineer and climbing guide who has logged a ridiculous amount of vert in a very short time, and is incredibly humble about his mind-blowing athletic prowess.

Cody led our small group on a tour to the back of Snowmass, where we did a few 1000 foot tours and rode creamy spring lines. It was a brisk, but bright and sunny spring day where temperatures wavered from the top of the peak, to the valley. Throughout it all, we were comfortable in our A-Cad Jacket and Bibs. They were breathable as we huffed and puffed up the skin track, but also kept us warm when then wind howled at the summit.

The fit was feminine, and freestyle-forward without any of the crunch or bulk in most three-layer outerwear. The bibs, which feature multiple strategically placed pockets, ample venting, and a side-entry zip that make it easy to take a swift backcountry wee, were easily our favorite part of the kit. Solid fitting bibs that aren’t too bulky in the boob or booty area are sometimes hard to come by, and these were form-fitting all around.

Our guide guy, Jack Cody waving hello and wearing the Men’s Futurelight kit.

Our guide guy, Jack Cody waving hello and wearing the Men’s Futurelight kit. The second day of testing, we had an even smaller group and set our sights on summiting Ski Hayden. It’s a 13,361’ peak with a beautiful face full of milky spring lines. Our skin up was a bit of a slog, slow and steady through the wooded subalpine, then past treelike onto the summit.

We kept our shell on for the majority of the skin, but did have to take it off once our heart rate started pumping and the sun beamed down some 40+ degrees. We had tossed back several tequila sodas the night before on The North Face’s tab, and seemed to sweat them all the during that skin, but never felt wet, or stinky. The jacket was just as easy to throw back on when the wind picked up near the summit.

While there is much more testing to be done with FUTURELIGHT, our initial impression has us waving the flag of acceptance. It’s incredibly lightweight, breathable, and even a bit fashion forward, which is nice to see coming from the ever-tech TNF.

Jack Cody in men’s Futurelight kit, ready to drop.

Jack Cody in men’s Futurelight kit, ready to drop. We’ve yet to test FUTURELIGHT in any dumping conditions or wet weather, so as far as waterproofing, stay tuned for test two.

The Aspen launch was the first widespread test of FUTURELIGHT, which releases this fall with some 30-plus products including jackets, shells, pants, gloves, and tents.

FUTURELIGHT will officially debut in the marketplace in 6 months.

Products Tested:

M/W A-CAD Jacket

-Mechanical stretch fabric with warm backer.

-Fixed, helmet compatible drop hood with riveted cord-lock adjustment system.

-Two-way, adjustable hood-management system.

-#5 YKK® AquaGuard®, two-way center front zip, pack-compatible pit-zip vents, two zip chest pockets and pass through pocket.

-Jacket-to-pant integration.

MSRP – $599

100% recycled polyester with brushed tricot backer and DWR finish

930 g (M) / 830 g (W)

n.

M/W A-CAD BIB

-Three-layer construction.

-Stretch fabric with warm backer and adjustable suspenders

-#5 YKK® AquaGuard® side-entry zip and harness-friendly, two-way zip-

Knee-to-knee inner-leg vents and integrated crotch gusset.

-Chimney Venting system and StretchVentTM gaiters with gripper elastic and boot hook.

system and StretchVentTM gaiters with gripper elastic and boot hook.

-Jacket-to-pant integration.

MSRP – $549

96% recycled polyester, 4% elastane stretch double weave upper bib with DWR finish

100% polyester suspender panels, lower body, knees and lower legs with brushed tricot backer and DWR finish

100% nylon kickpatches

820 g (M) / 720 g (W)

About FUTURELIGHT from The North Face:

The North Face is unveiling FUTURELIGHTTM, the world’s most advanced breathable-waterproof outerwear technology developed using nanospinning technology and sustainable practices. FUTURELIGHTTM was born in the mountains out of specific requests from our global athlete team looking for increased performance and breathability in their waterproof gear. FUTURELIGHTTM allows The North Face to adapt and optimize the air permeability, stretch and hand feel of any garment depending on the activity or environment.

Check out more gear features here.

The post What is FUTURELIGHT? – The North Face Launches New Fabric in Aspen, Colorado appeared first on Snowboard Magazine.